Metering pumps have emerged as the game-changer across a wide variety of industrial landscapes, marking a forward-thinking shift toward precision dosing due to their ability to accurately measure and administer dosages. In the process of redefining how industries control and manage fluid processes, metering dosing pumps are being integrated into various applications. Among these applications are water treatment plants and pharmaceutical manufacturing facilities, among other related facilities. Stunning Examples of Water Treatment:Metering dosing pumps are becoming increasingly popular for use in water treatment, and municipalities and industrial facilities are quickly adopting them. In order to achieve the desired level of purification, these pumps guarantee that the chemicals are injected precisely. This not only helps to improve the quality of the water, but it also contributes to making the treatment processes more effective and less harmful to the environment. The process of injecting chemicals and additives into wells is an essential part of the oil and gas industry, and metering dosing pumps are among the most important components of this process. The optimization of the oil and gas industry is facilitated as a result of this. In addition to reducing the likelihood of obstructions occurring in pipelines, the utilization of this precise dosage not only improves the efficiency of the extraction process but also satisfies the stringent requirements that are associated with the production of oil and gas.

dosing pump cleaning and repairingpump.com

dosing pump cleaning and repairingpump.com

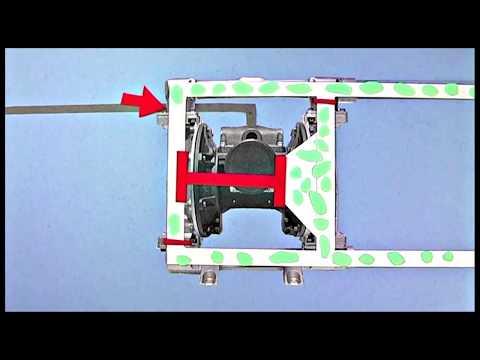

How a diaphragm pump works.pump.com

How a diaphragm pump works.pump.com

It is interesting how does a metering pump work. Metering pumps are being utilized by pharmaceutical manufacturers in the production of medications, which is putting the pharmaceutical industry at the forefront of excellence. Measuring pumps have the capability of providing precise dosing. Two of the factors that contribute to the formulation of drugs that are of high quality and standardized are the injection of pharmaceutical ingredients and the mixing of those ingredients in an accurate manner. Carrying Out Preventative Maintenance:Performing routine maintenance on metering pumps is absolutely necessary in order to guarantee that they will last for a long time and continue to function effectively. It is essential to carry out routine inspections of components such as valves and diaphragms in order to achieve the highest possible level of performance by the system. Getting the Calibration RightCalibration that is carried out in the appropriate manner is required for accurate dosing. It is helpful to maintain consistency in the delivery of fluids by ensuring that the pump is calibrated on a regular basis in accordance with the specific application.

Penetration of the Global Market: Chinese manufacturers have been able to successfully penetrate the global market by supplying metering dosing pumps to industries located on all continents. This has allowed them to successfully penetrate the global market. China has emerged as a significant player in the global market for industrial pumps as a result of the country's unwavering commitment to quality and dependability in their products. Measuring and dosing pumps manufactured in China stand out as an industry leader, making significant contributions to the development of fluid control technology on a global scale. This is due to the fact that businesses all over the world are implementing precision dosing solutions in order to enhance their operational effectiveness.